Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

| Axle Loc'n | Year | Description | Shaft | Shaft | Ratio | Air Locker |

| Diameter | Spline | Part No. | ||||

| Front | 2007 on | All models | 34.8 (1.37") | 34 | All | RD1516 |

| Rear | 2007 on | All models | 34.8 (1.37") | 32 | All | RD152 |

| Front | 1998 on | 8" dia. RG, IFS, 50mm bearing ID | 33 (1.31") | 30 | All | RD131 |

| 1998 on | Live axle suspension | 33 (1.31") | 30 | All | RD132 | |

| Rear | 1998 on | All models | 34.8 (1.37") | 32 | All | RD152 |

| Front | 1996-03 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD90 |

| 2003 on | 8" dia. RG, IFS clamshell, 53mm BRNG | 33 (1.31") | 30 | 3.91 & UP | RD1113 | |

| 3.73 & DN | RD1213 | |||||

| Rear | 1996 on | 8" dia. RG, 10 bolt | 33 (1.31") | 30 | All | RD132 |

| 2009 on | 8.15" dia. RG, 12 bolt (shimmed) | 33 (1.31") | 30 | All | RD193 | |

| Front | To 1989 | 12 bolt, full floating | 33 (1.31") | 30 | All | RD1421 |

| 1990-97 | 10 bolt, full floating | 33 (1.31") | 30 | All | RD132 | |

| Rear | 1969-76 | 12 bolt, semi floating, 45mm bearing ID | 33 (1.31") | 30 | All | RD1531 |

| 1977-89 | 12 bolt, full floating, 45mm bearing ID | 33 (1.31") | 30 | All | RD1421 | |

| 1990-97 | 12 bolt, full floating, 50mm bearing ID | 33 (1.31") | 30 | All | RD142 | |

| 1977-92 | 12 bolt, semi floating, 50mm bearing ID | 33 (1.31") | 30 | All | RD153 | |

| Rear | Dana 60 | 33 (1.31") | 30 | 4.56 & UP | RD162 | |

| 4.10 & DN | RD163 | |||||

| Front | All | 10 bolt | 33 (1.31") | 30 | All | RD1321 |

| Rear | To 1985 | 10 bolt, 45mm bearing ID | 33 (1.31") | 30 | All | RD1321 |

| 1986 on | 10 bolt, 50mm bearing ID | 33 (1.31") | 30 | All | RD132 | |

| Front | All | 10 bolt, live axle | 33 (1.31") | 30 | All | RD1321 |

| To 2005 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD902 | |

| 2005 on | 8" dia. RG, IFS clamshell, 53mm BRNG | 33 (1.31") | 30 | 3.91 & UP | RD1113 | |

| 3.73 & DN | RD1213 | |||||

| Rear | To 1988 | 4 cylinder, 45mm bearing ID | 33 (1.31") | 30 | All | RD1321 |

| 1988-05 | All models, 50mm bearing ID | 33 (1.31") | 30 | All | RD132 | |

| 2005-15 | Adjuster nut models, 50 or 53mm bearing ID | 33 (1.31") | 30 | All | RD1324 | |

| Dana Spicer shim adjusted models. | 33 (1.31") | 30 | All | RD1335 | ||

| 2015 on | 8.9" dia. RG, 12 bolt (shimmed) | 34.8 (1.37") | 32 | All | RD232 | |

| Front | All | 10 bolt, live axle | 33 (1.31") | 30 | All | RD1321 |

| To 2003 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD902 | |

| 2003 on | 8" dia. RG, IFS clamshell, 53mm BRNG | 33 (1.31") | 30 | 3.91 & UP | RD1113 | |

| 3.73 & DN | RD1213 | |||||

| Rear | 1984-88 | 4 cylinder, 45mm bearing ID | 33 (1.31") | 30 | All | RD1321 |

| 1988-10 | V6, 4WD, 50mm bearing ID | 33 (1.31") | 30 | All | RD132 | |

| 1988-10 | V6, 2WD, 45mm bearing ID | 33 (1.31") | 30 | All | RD1321 | |

| 2010 on | 8.15" dia. RG, 12 bolt (shimmed) | 33 (1.31") | 30 | All | RD193 | |

| Front | 2005 on | 8" dia. RG, IFS clamshell, 53mm BRNG | 33 (1.31") | 30 | 3.91 & UP | RD1113 |

| 33 (1.31") | 30 | 3.73 & DN | RD1213 | |||

| To 2004 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD90 | |

| Rear | To 2015 | 8.4" dia. RG, 12 bolt | 33 (1.31") | 30 | All | RD129 |

| 2016 on | 8.0" dia RG, all autos excl. OE Locker Equipped | 33 (1.31") | 30 | All | RD132 | |

| 8.9" dia RG, all manuals & all OE Locker Equipped | 34.8 (1.37") | 32 | All | RD232 | ||

| Front | 2007 on | All models | 34.8 (1.37") | 34 | All | RD1516 |

| To 2006 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD90 | |

| Rear | To 2006 | 8.4" dia. RG, 12 bolt | 33 (1.31") | 30 | All | RD129 |

| 2007 on | 10.5" dia. RG | 36.8 (1.45") | 36 | All | RD146 | |

| Front | 2007 on | All models | 34.8 (1.37") | 34 | All | RD1516 |

| To 2008 | 7.5" dia. RG,10 bolt, IFS | 28 (1.1") | 27 | All | RD90 | |

| Rear | To 2007 | 8.4" dia. RG, 12 bolt, live axle | 33 (1.31") | 30 | All | RD129 |

| 2008 on | 10" dia. RG, IRS | All | TBD | |||

| Front | 2005 on | 8" dia. RG, IFS clamshell, 53mm BRNG | 33 (1.31") | 30 | 3.91 & UP | RD1113 |

| 3.73 & DN | RD1213 | |||||

| Rear | 2006-09 | 8" non-factory locker model | 33 (1.31") | 30 | All | RD132 |

| 2010 on | 8.15" dia. RG, non-factory locker model | 33 (1.31") | 30 | All | RD193 | |

| Rear | TBD | 10.5",34 SPL | 34.8 (1.37") | 34 | All | RD183 |

If you want to know what makes and models of cars they are suitable for, you can contact us directly to get them.

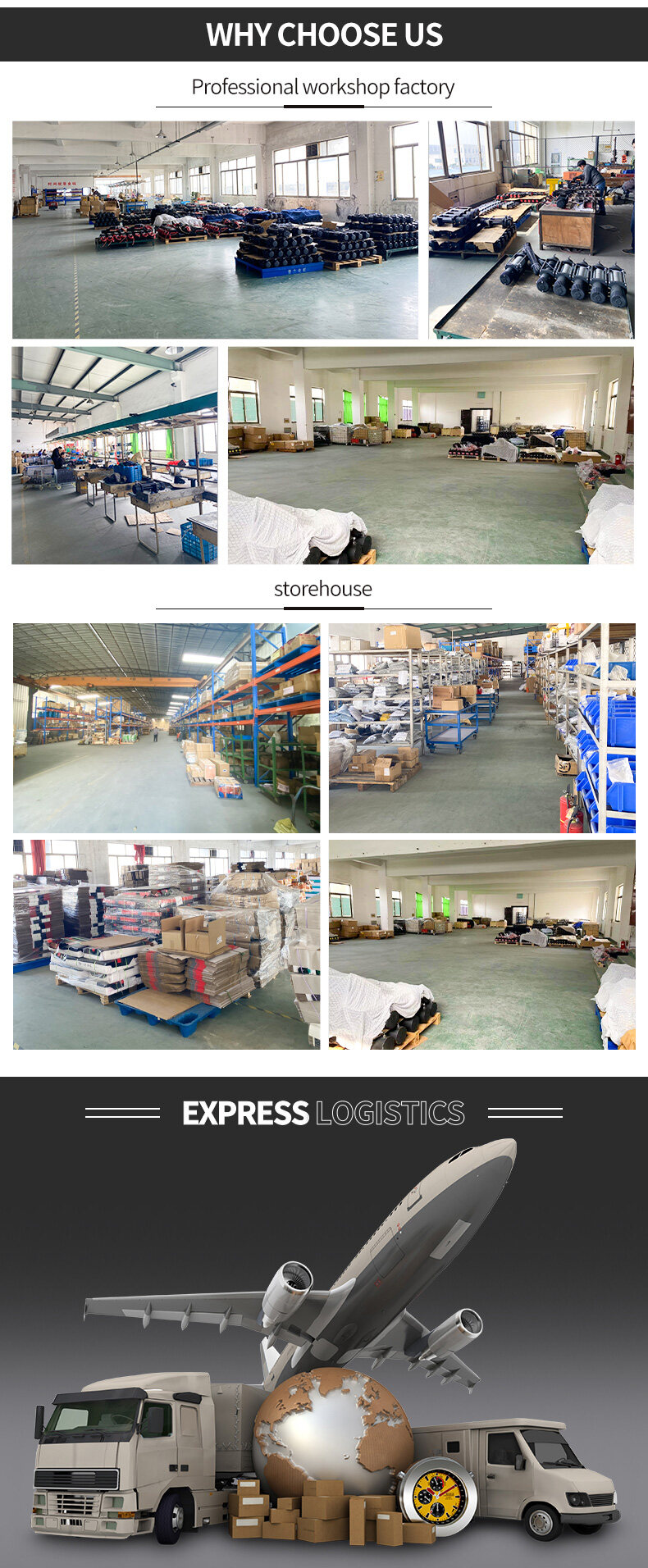

Auto-Cross country —— The best choice for field sport. WORKER is a highly specialised winch manufacturer situated in Ningbo, Zhejiang province, the most developed area in Changjiang, now the economic hub of China. Our premises cover an area of 16000 square meters, comprising more than 15,500 square meters of factory floor space and offices for our 100-plus employees. Our manufacturing plant has state-of-the-art assembly lines, together with in-house precision die-casting, CNC machining, heat treatment, polishing, high-pressure cleaning and finishing facilities.

We also have the most advanced, fully-automated intelligent electric motor and winch testing facilities in the winch industry, to ensure the very highest standards of product reliability and durability. Established in 2005,WORKER began a highly progressive and intensive R & D programme into winch design, using the very latest in technology, to improve product performance and efficiency in production. We currently own patents on our many improved winch design features and strive to maintain our unsurpassed build-quality and outstanding value.

Today, WORKER has a comprehensive range of winch products and is developing more, including the first in a series of efficient hydraulic winches, for the commercial and military markets. Our factory is currently producing 100,000 winches a year making us the one of the largest winch manufacturers in China. Winches which are exported to Europe, North America, Australia and many other countries, both in the guise of our own brand as well as OEM’s for many top names. Our philosophy is simple; to stay ahead in our business by being totally professional, but have fun doing it by remaining young in our hearts and minds.

We have passed CE CERTIFICATE, TUV CERTIFICATE, IATF 16949 CERTIFICATE, ISO14001:2015 CERTIFICATE and ISO9001:2000 CERTIFICATE.

Parts assembly - Finished product assembly - Inspection and testing - Packing into boxes

We support sea, air and land transportation, delivery to door point (refer to WE COULD BY SEA OR AIR OR DOOR TO DOOR SHIPPING). Products are generally shipped within 35 days, according to the product to provide bubble and carton packaging to ensure product safety.

Q: What is the MOQ?

A: Each product has different requirements, please contact us for specific products.

Q: What is your delivery time?

A: 35-40 days

Q: What is the payment method?

A: 30% PAYMENT AFTER CONFIRMED THE ORDER, 70% PAYMENT WHEN WE ARE READY TO SHIP.

Q: How do you guarantee the quality of the products?

A: We have strict factory testing to ensure the quality of each product.

Q: Are you a factory or a trading company?

A: The integration of industry and trade.

Q: Where is your factory?

A: Ningbo, if you want to visit, you can contact us.

Q: Are customized services available?

A: As long as you tell us your needs, we will provide you with customized solutions.

Q: Do you support OEM and ODM?

A: We support OEM and ODM services, if you need, you can contact us.

Q: Why choose us?

A: We are a professional manufacturer, focusing on the manufacture of 4*4 auto parts.

Strict inspection and testing process to ensure the quality of each product.

High-quality after-sales service to solve every problem related to auto parts.

Q: How long is the product warranty period?

A: 1-3 years.

Air locker is a brand of truck air locker and a good helper for off-road vehicles. The air locker store has their address on their website, so you can buy it at any store. If you find a cheaper price elsewhere, it may be fake.

Designed for hard off-road use, the air locker uses special materials, advanced products and superior experience. The performance of air lock is superior to the traditional vehicle lock system in many aspects. When you purchase air locker, you will also get the corresponding installation guide.

We make the best off-road air lockers in the world. This new design is designed to help drivers at all levels - experienced or not! With patented high-quality parts and low price, it is very suitable for all kinds of off-road vehicles.

When it comes to off-road and rough terrain, your vehicle must have excellent driving stability even in harsh conditions. Air lockers are easy to install air suspension devices. It helps improve off-road capability and stability by reducing body inclination without rigid suspension kits and towers. After installing air locker, your truck or SUV will be able to go anywhere you want!

Each air locker consists of several parts: installed air locker, air pressurization device, air reservoir with pressure gauge or multi-function pressure gauge, and all hoses and clips if necessary. Compatible with tire sizes from 320 mm to 1130 mm.

The air locker block is designed for off-road machines and still has many of the same design aspects as a standard air locker. The off-road air locker has thicker beams, and these additional gusset plates help to strengthen the shell and prevent lateral forces from rocks and trees or accidental damage during off-road riding.

You can whitewash it as you like, but the fact is that many aftermarket 4x4 modifications we spend time flattering are designed to improve the way our vehicles do two things - maintain traction and overcome obstacles.

The same is true for locking the differential, but when deciding to lock the differential, we all need to make a key choice - Air locker or electronic locker?

Air or electrons?

Both differentials achieve the same goal, but in different ways. The air lock uses pneumatic pressure to lock the gear in place through the on-board compressed air source. This is usually activated by a switch on the instrument panel and the gears remain locked together until the pressure is released.

The biggest benefit of air lockers is that they are almost instantaneous (in fact, top-level ARB air lockers can be completed in less than a second), because there is no need to convert signals into actions - it is essentially an analog solution.

At the same time, the electronic locking differential (or electronic lock) uses an electronic switch to control a set of magnets, pull apart the two roller cams, and then engage the pin pushed into the side gear - locking the differential. In terms of appearance, their working principle is similar to that of air lockers. Except for the standard 12V, they do not need external power supply.

This is the main advantage of electronic lockers, because air lockers require on-board air compressors to operate. This means that electronic lockers are more reliable, which is why they are the preferred choice for many commercial users and manufacturers.

However, they are less instantaneous than air lockers, and some older models may take a few seconds to engage. At the same time, the more modern model 4 pinion electronic lockers are significantly faster.

Which would you choose? Tell us your needs, we can customize according to your requirements.